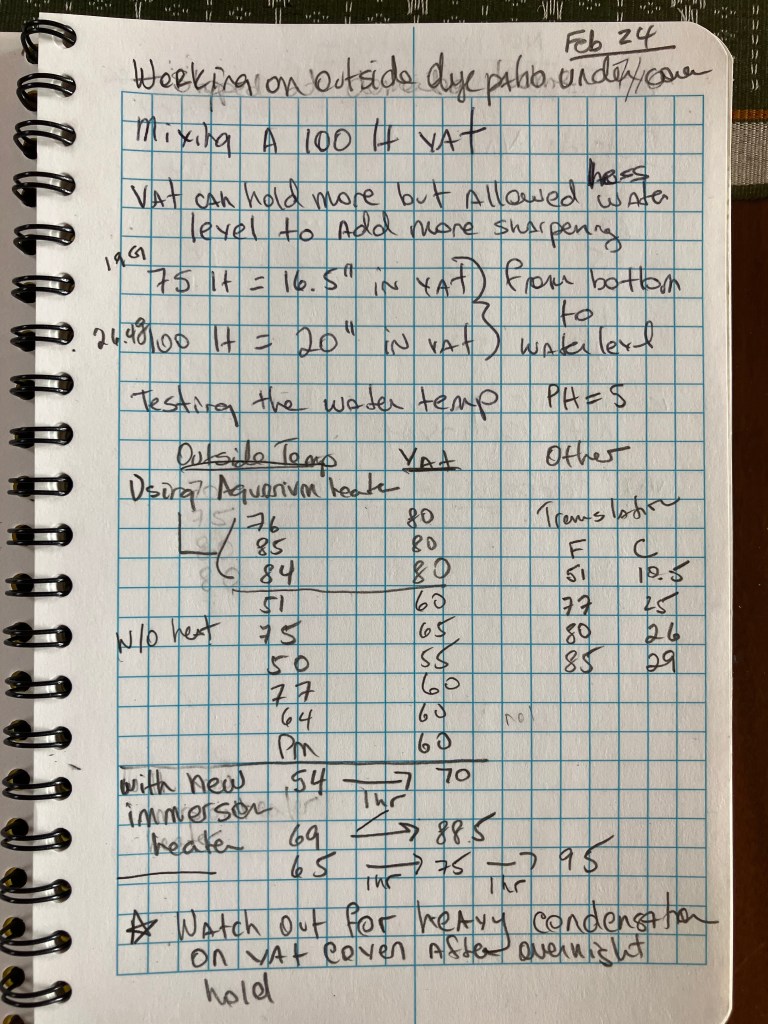

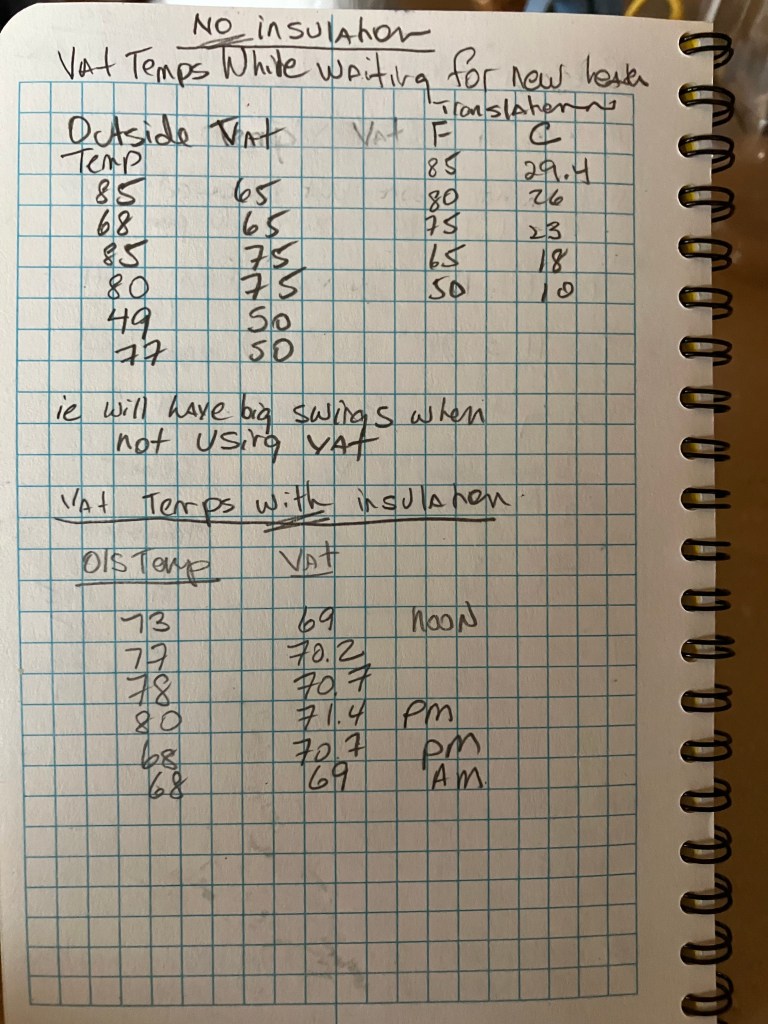

Let the mixing begin. I only wore my mask till all the powders were wetted out and not floating in the air. Now watching the heat. A watched vat does not get hot fast. Thanks to everyone that mixed before me in the February class by Elisabeth so I could ponder the process. Here is a link to her classes.

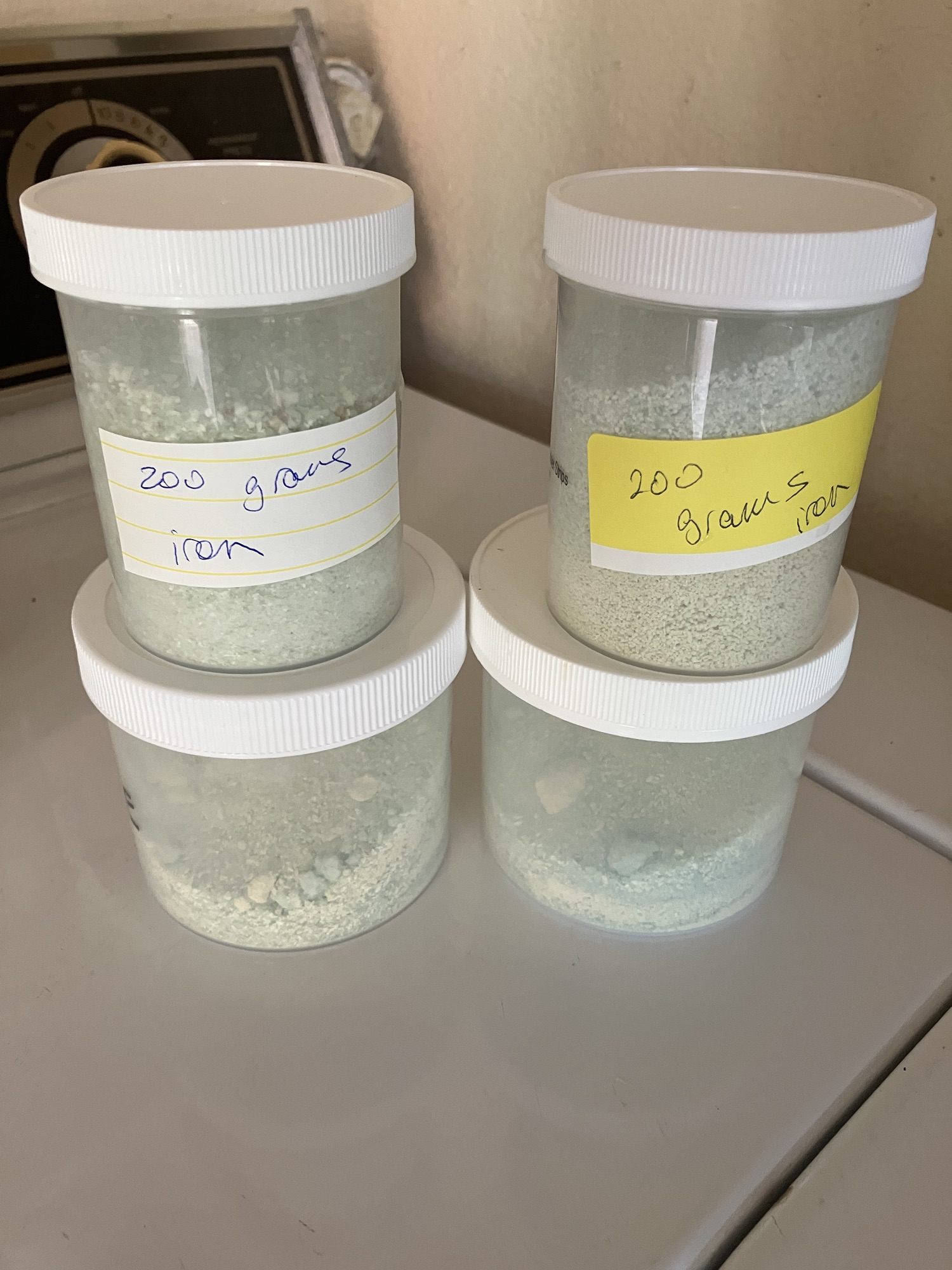

Ferrous sulfate and calcium hydroxide measured out. Got an idea of dry volume and water needed to dissolve.

Pasted indigo gets one more stir to suspend pigment in the water. I left it overnight to let lumps soften & settle.

Vessels have heated water and ingredients added to dissolve

Mental note, this vat has an indent on the bottom I need to stir into and around. Wish I had measured the width before I started dumping ingredients into the vat. There is always an “if only”.

And splat! I wish I could set up neat & tidy but I always find a way to drip with large vats.

Pasting the leftover lumps. This is washed & dried pigment from my large Fructose vat. I wash my old fructose paste with 9% vinegar to remove the calcium carbonate and drain thru filters. Solely for the purpose of removing sludge volume and storage. We will find out how the pigment works after washing on a large scale.

My plan is to find out if same process works for “iron sludge”. I do NOT know if this process works for iron vat sludge or the chemical impact, yet. I need to create some iron sludge. Hence this vat is starting up. The Sapa indigo dyers use their pigment season to season in a wood ash vat. I decided to try using vinegar to reduce the calcium in a sludge reduction effort and clean up for use.

Old lady way of moving water from point A to point B

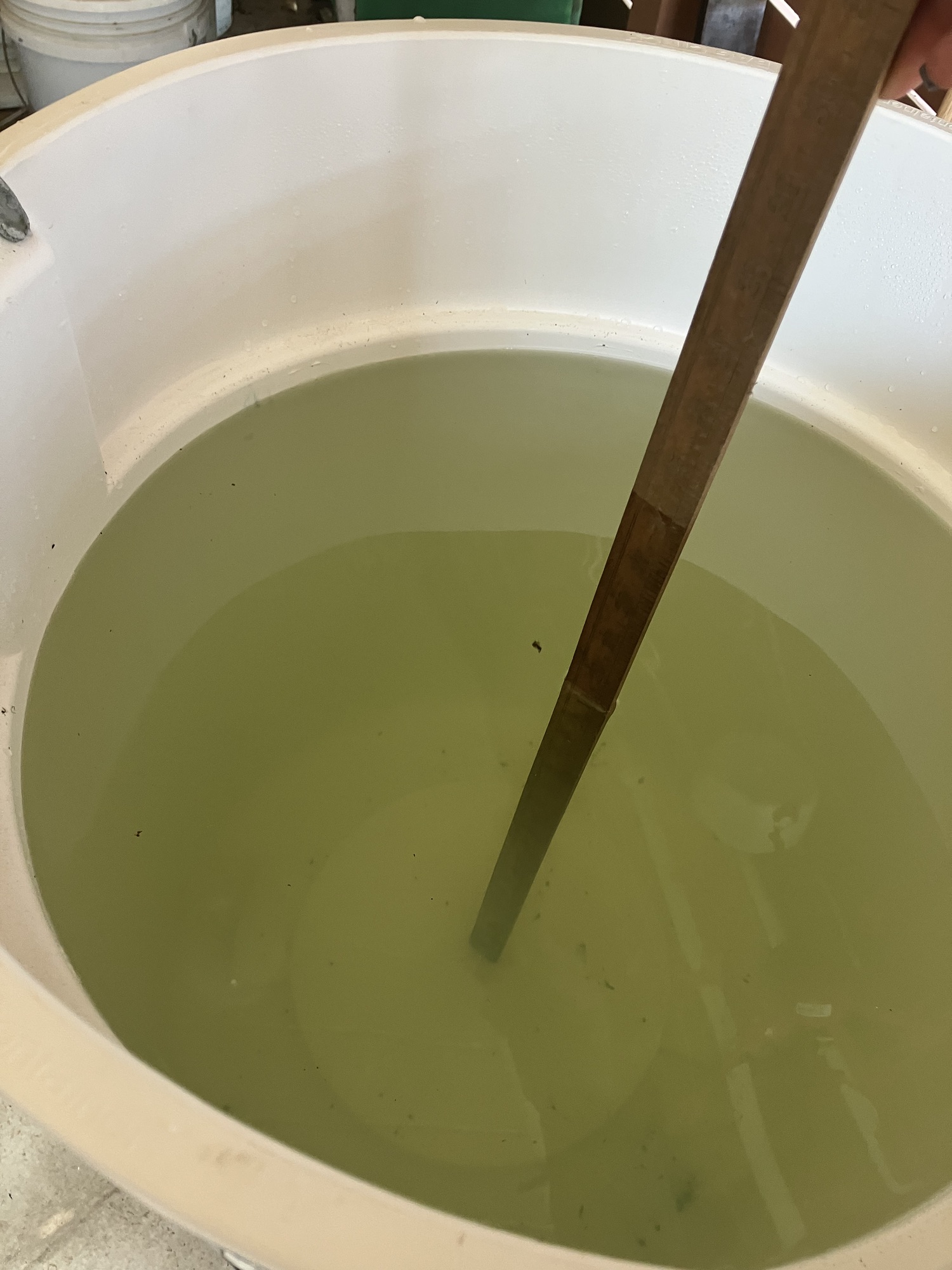

Nice & soupy, time to stir.

Stirring & stirring

Now I heat & wait for reduction. My sticks that support my heater are sitting on the handle indents within the bucket. No holes were made. I suppose holes would be safer. To me, if the sticks were left in place in the holes not much heat would escape. More importantly, I would be concerned with disturbing the structural integrity of the bucket sides by putting holes into the plastic. I am leaning towards putting holes or screw eyes in sticks and hold sticks by tying the handle. Right now I am still developing a relationship with my vat configuration. I’ll improve later.

You must be logged in to post a comment.