Note, SORRY guys, I accidentally deleted my blog post, my bad, let’s try this again.The 2020 season was time for experimenting with wet extraction of my Indigofera Suffruticosa and my Japanese Indigo. Prior years, due to our Texas heat and extreme weather, it was easier to pick the leaves and dry them for storage while I became acquainted with growing the plant itself in the Texas Hill country. You gotta keep the plant alive to reach the indigo cycle.

Let me just say for the record that I am extremely glad that Stony Creek Colors and Botanical Colors are vendors for indigo pigment. I enjoy growing the indigo varieties, but for my 110 gallon indigo vat I will never grow enough indigo to fill that vat adequately to obtain dark color for my paste resist work. However, I do small batches with my home grown indigo when I do stitch shibori or just need to overdye yarn skeins for weaving. Both methods, buying or growing are viable depending on your vat size or intent.

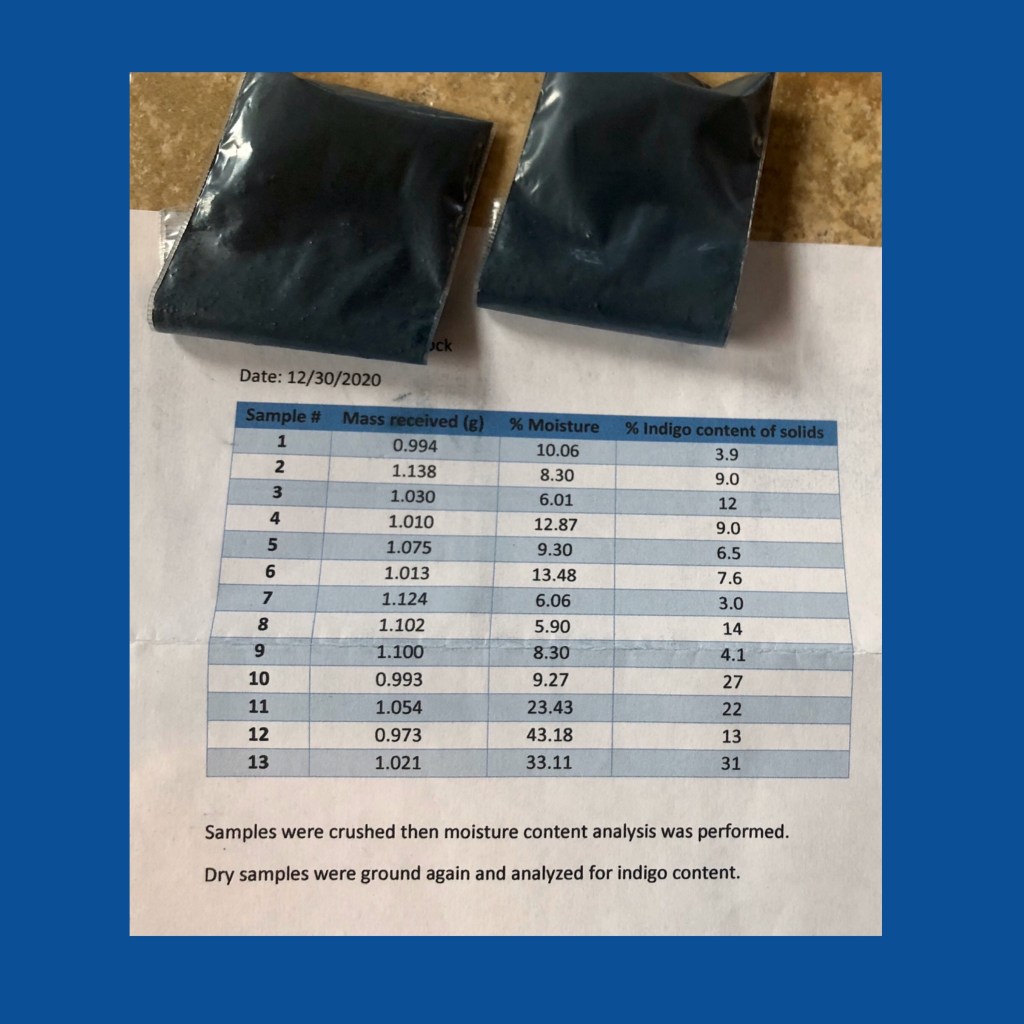

Below is my indigo pigment chart provided by Stony Creek Colors after analyzing my home grown pigment content, comparing vinegar wash versus no wash, and a comparison of Japanese Indigo versus Indigofera Suffruticosa. I submitted a total of 13 one gram samples over the season to test for pigment content. In other words, I process 13 batches over the growing season, kept notes on leaf weight, washing and kept them separate for testing.

Each test batch of dried pigment was 1 gram more or less. Summer Arrowood, Senior Research Chemist, was most patient in explaining their testing process. I had a question on the above chart on the last 2 columns on the right of the chart I received with my above testing. This is what I asked. “What is difference on your table between Indigo Content of Solids vs Overall % indigo of sample. Are you spinning out moisture from my sample or drying it further? Is the Overall % more indicative of indigo contained? I am having trouble differentiating between the phrases since they are referring to the same sample.”

Response from Summer Arrowood, Senior Research Chemist, “Your samples were quite moist, as much as 43% water in the case of #12. In order for our analysis to work the samples must be very dry. I dried the entire sample on a moisture balance and then took the dry material and analyzed it for indigo content. The ‘Indigo content of solids’ refers to this analysis. To get the ‘overall % indigo’, I used the moisture content and the indigo purity to calculate the % indigo of the sample as you sent it, including the water mass.”

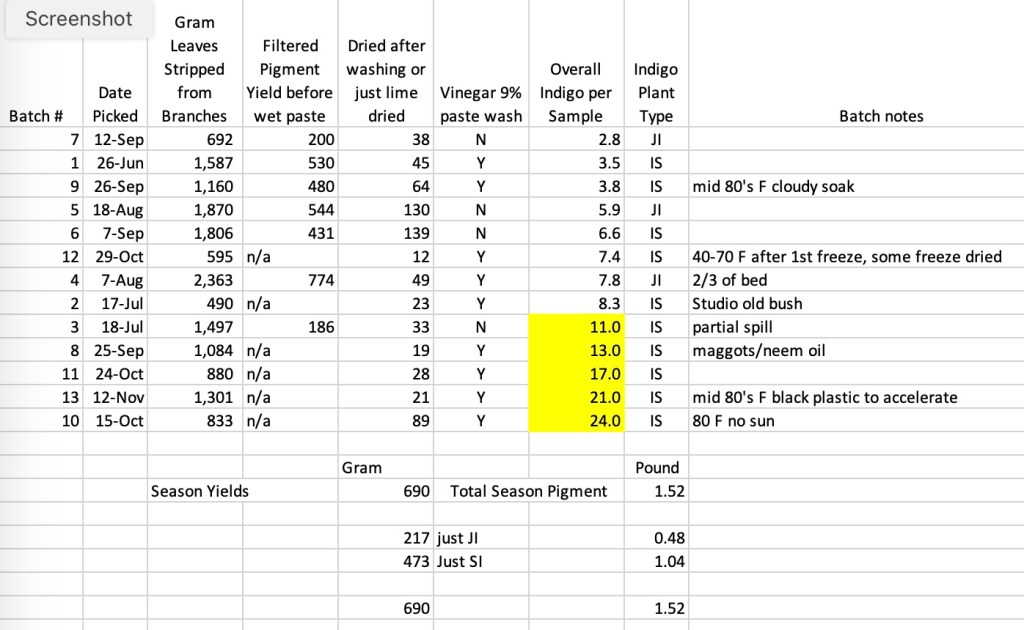

My big surprise was the LATER in the season that I harvested my Indigofera Suffruticosa the HIGHER my indigo content went. I expected the indigo content to be much higher in July and August with the sun intensity, instead, October and November growth gave the greater yield in the Texas Hill country. This was in two – four year old shrubs. My field notes chart combined with the Stony Creek pigment report sorted by yield is below. Of course there are other notes on leaf weight/sun/process but this is an abbreviated compilation.

I’ve added my growing notes in the chart below in addition to the testing performed by Stony Creek Colors on my samples submitted. Chart is sorted by Indigo per Sample yield but I’ve included data to show you the seasonal cycle. The late season results were surprising. I was happy with the seasonal yield although it does include 4 batches that did not get washed to remove the calcium carbonate. I included the weight of pigment before washing and after washing. Towards the end of the season I had committed to washing with vinegar on all my batches and felt what I had measured earlier in the season gave me info I needed to see the difference. I calculated the the reduction in volume stored was about 80-90%.

I feel that reduction in volume was sufficient to justify the extra time washing pigment.As indicated in the indigotin chart, my Japanese Indigo did not perform well at all. I do not know why, but I suspect the intense sun here in central Texas had an impact on indigotin production. Even though I use a sunshade that does not seem to help the indigo production in the Japanese Indigo. Even looking at early season harvest my indigo levels were not high.

Details for those who want to know more….

In summary, I did only wet extraction in 2020, washed my pigment and compared seasonal extracts, washed vs not washed pigment %’s. Stony Creek Colors was very helpful in explaining their testing methods and indigo content % measurements to me. Having been educated by the grower/dyers in the FaceBook Indigo Pigment Extraction group I made the plunge. I am a measuring person, the type that likes to have an idea of what effort I am putting in and what I am getting out of it. My observation is that dried leaves were giving me good color on a small scale but exactly how much pigment are the dried leaves giving me? Wet extraction seemed to be the best way to measure the picked leaves, render them down to pigment and get a measure from that effort. I am a measuring person, so I have records of my leaf weight before I dry them to compare to the wet extraction results. I am also a frugal and “older” indigo farmer. I only want to pick as much as my limited equipment could handle and that I could lift. I had a good idea what I could pick, strip and lift in the AM and set out in my 5 gallon buckets to soak in the sun for a couple of days for the wet extraction.

My bushes told me what I needed to cut as I could see the bluish tinge in the leaves. I trimmed both varieties for shape and for the winds to avoid damage during storm seasons. My Indigofera Suffruticosa shrubs can last for at least 4 or 5 seasons if I don’t have a killing frost or cold spell. It is now game over due to our major freeze and power failure we had in February 2021. This 2021 spring I am back to restarting my plants from seedlings. It will regrow! My plan was to double check my testing but with my bush loss this year, I had a test set back. 2022 will be the year to test the IS again in central Texas. I set aside growing Japanese Indigo as I am focusing on prepping the IS beds which had settled over 3-4 years as the shrubs grew and this is my time to reprep those beds for new plants. Heaving Texas soil takes time for a home farmer.

Washing Indigo Yield with 9% Vinegar

The kicker in the wet “measuring” process is the calcium hydroxide used to flocculate the indigo and get It to settle for filtration. Despite trying several methods of just using water settling the indigo, my observation is that this method takes way too long for the indigo to settle to a useable filtration state. Using the calcium hydroxide is much more efficient for me and enabled me to get on with the process and my life outside of indigo. But, the 4-6 tablespoons of calcium hydroxide added for flocculation adds weight and one cannot get a clean measurement of just pigment. So I investigated washing my pigment with 9% vinegar to cleanse it of the calcium carbonate which the calcium hydroxide inevitably becomes when mixed with water and oxygen. Leaving it as paste just adds to bulk and one must always add more slaked lime to reactivate the indigo chemistry to get the bonding. Plus washing reduces the sludge. I have heard mutterings that the vinegar washing impacts the indigo paste but I have not found anything in writing. Folks do wash only with water, next time I will try that against a vinegar wash and compare.

On a side note, I mixed ONLY calcium hydroxide and water and used my sump pump as if I were mixing a flocculation brew to create a test. I washed it about four times and did see a major reduction in calcium carbonate volume. My observation is that I had the greatest reduction with the 9% vinegar after two washes. Wash 3 & 4 worked but just seemed like extra effort just because I could. Unfortunately, at that time my mom was having a round of health problems, so I did well just to complete the vinegar washes and capture photos. My intent to measure reduced volume each time was thwarted by real life outside the dye patio. Sometimes I just had to walk away from the dye patio process and leave everything to wait for me until mom was cared for. But visual observation of the process showed the reduction was substantial despite the lack of measurement of the process.

Watching the vinegar work on the calcium carbonate

Two Looms was very generous with information as to how they clean their indigo with citric acid or hydrochloric acid. However, we are on a well and septic system with direct discharge to the Pedernales River and I felt like that journey was beyond my chemical skill set, hence 9% vinegar. I haven’t tried 20% agricultural vinegar but it is definitely on my list. I need to investigate safety measures needed for that level of acid and recommend that one check the MSDS data to understand the risks of 20% agricultural vinegar. It is a chemical that can hurt you. Nine percent works just fine for me. We are sitting on alkaline limestone, so I don’t feel real bad about discarding vinegar dissolved calcium carbonate water into our natural system.

I found 5 gallon buckets and the Dudas 25 micron filter really useful for washing the pigment in manageable amounts. I usually wash it with a 3:1 9% vinegar to water at least twice AFTER the normal filtration is done. I found the wet paste mixed well with the vinegar brew. One learns to mix the vinegar in slowly or you get the lava foam effect and can lose solution from an overflow accident. Keep an eye on the foam reaction. That is the vinegar hitting the calcium carbonate and dissolving it. This is a good thing except when it overflows your filter. This step takes time but if you’ve been extracting indigo from your leaves you aren’t in this for a quick process.

The benefit of washing with vinegar means I am not storing wet paste and the dried and washed pigment is MUCH easier to grind. The volume reduction is significant between wet paste and dried pigment and does not require a refrigerator or extra storage space. If you do the math on my chart above you’l see that I had a 60 – 90% reduction in volume. Here is a link to a YouTube video on my vinegar washing, you’ll bounce over to YouTube, sorry, WordPress changed some functionality and I could not get it directly into my blog. This gives you a view of how I wash my home grown indigo and ALSO how I wash the Big Jar at the end of the season to retrieve my indigo for the next solar season. I learned about storing mud from one season to the next from the indigo masters in Sapa, Vietnam who were very genorous with their knowledge. I met them thru Above The Fray – Textile Travel, a great journey with friends a couple of years ago.

I’m glad I went to the trouble and expense to separate out batches over the season and get the analysis of indigo content. My next step is to compare my dried leaf output to the wet extraction to get a general idea of what 100 grams of dried leaf indigo gives me compared to my pigment. More math is in my future when I am in the mood.

This was an extremely long blog entry. Any suggestions, questions or comments would be most welcome. Deb Mc

Such a process! Do you then take the washed indigo pase and dry it into cakes to grind up for the next time? I never got this far with growing indigo to process for vat making as I just don’t have enough space nor do I want to use the water for growing it that is required here.

I applaud your tenacity and your data recording! Thanks for sharing the process Deb!

LikeLiked by 1 person

I did dry it and broke it up in chunks to store. The washed chunks definitely grind easier & are much less volume to store. The washing took out 70-90% bulk. Easier to hold and combine as one grows it.

LikeLike

Congrats on such a scientific study ! Do you know if indigo was / could be grown in the 1800’s in Texas territory? Are there native varieties?

I am especially interested to know about fabrics woven and handwovens that were dyed in indigo during slavery? Could you refer me to anyone or any organization that knows about weaving done in Texas during slavery? Any academic or any Guild that might have info?

I am a weaver in Colorado and a descendant of a plantation owner in Hempstead. I am working with students at Prairie View to learn about weaving and fiber arts during slavery and Emancipation. Any hints? beckytwo@msn.com Becky Vanderslice

LikeLiked by 1 person

Let me think on it, Donna Hardy is doing research further east of Mississippi in the Carolinas. I am pretty clued in on weaving history but not the slavery angle other than what others have written about. I have not seen first hand writings. It might be worth pursuing the Hispanic and Black history in Texas. I know a dyer has found wild Indigofera Suffruticosa fields near Bastrop on the Colorado. We don’t know how it got there. I guess this is my long winded answer to I don’t know and the research field is wide open for you and your students.

LikeLike

Also, look for Donna Hardy as Sea Island Indigo, in Georgia, she is on in the FB Extraction group and on Instagram.

LikeLike

Sea_Island_Indigo on IG just posted a stack of history books you & your students might be interested in.

LikeLike

So happy to call you ‘FRIEND’. The first time I heard Casey Galloway mention you, I made note of your name and started a search to find you. You are an inspiration to all of us. Your email this month is ‘blockbuster news’ that present Indigo lovers and future lovers and Indigo dyers will benefit from. Keep up the excellent work and study dear friend.

LikeLiked by 1 person

Blush….thank you, just another way to measure indigo

LikeLike

Hi..thank you so much for this great blog. Indigo that regrow is a dream. I’m in Canada so that’s just not happening here. Do you get two harvests in 12 months? Thanks again. Tara

LikeLiked by 1 person

I grow Japanese indigo & Indigofera Suffruticosa, you are right the weather up there is against you. Depending on weather I get more than two harvests a year. I don’t know exactly how far north you are in Canada but Japanese Indigo does much better in your climate. Start seedlings indoors early in the season, set out after killing frosts and protect from frost. Are you a member of FB Pigment Extraction Group? Folks from all growing zones around the world can answer questions.

LikeLike

This is fantastic Deb. Thank you for taking the time to write all this up and share! Im with you on storing pigment dried and measuring the weight as compared to harvest leaves weight to know the yield. You’ve inspired me to send some pigment samples away to SSC.

Im slowly making my way through my dried leaves cache and need to size up in vessels soon. Im keeping my eyes peeled for a big jar!

LikeLiked by 1 person

We know we do count leaves! Call SSC to understand how they need it packaged by you for testing. The good news is you get a beautiful ground indigo batch back after they test.

LikeLike

I admire your careful work and attention to detail. I was trained as an analytical chemist and you must have been one in a previous life! Also admire your ability to grow indigo. Here in the Northeast it is a challenge and an art.

LikeLiked by 1 person

Love seeing the results of your work! Thanks for sharing this progress! Sarah, Stony Creek Colors

LikeLiked by 1 person